- Blogs

- Full Fill vs Partial Fill Cavity Wall Insulation Board

Full Fill vs Partial Fill Cavity Wall Insulation Board

Cavity wall insulation is a crucial element in building construction, contributing to improved energy efficiency and decreased heat loss. Two primary types of cavity wall insulation exist full fill and partial fill.

Full-fill insulation entails completely filling the cavity with insulation material, forming an unbroken thermal barrier that enhances energy efficiency, minimizes heat transfer pathways, and reduces air infiltration. However, meticulous installation is necessary to prevent thermal bridging, and this method can be more costly than partial fill insulation.

Conversely, partial fill insulation leaves an empty space between the insulation and masonry. While it is easier and faster to install, cost-effective, and suitable for retrofitting existing buildings, it may result in air gaps and have lower overall insulation effectiveness compared to full-fill insulation.

These distinctions in installation process, effectiveness, cost, and suitability for new construction or retrofitting differentiate full fill and partial fill cavity wall insulation.

Key Takeaways

- Full fill cavity insulation creates a continuous thermal barrier and maximizes energy efficiency.

- Partial fill cavity wall insulation is a cost-effective option for insulation and is suitable for retrofitting in existing buildings.

- Full fill insulation requires precise installation to avoid thermal bridging, while partial fill insulation may leave air gaps between insulation and masonry.

- Full fill insulation offers higher overall insulation effectiveness, while partial fill insulation has lower soundproofing capabilities.

Full Fill Cavity Insulation

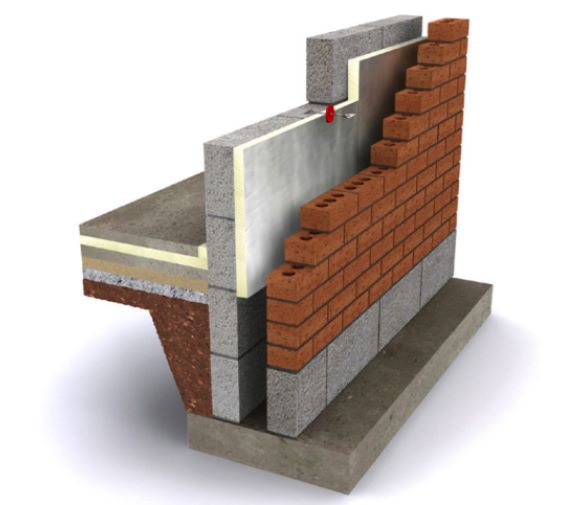

Full fill cavity insulation completely fills the cavity and creates a continuous thermal barrier, maximizing energy efficiency and enhancing overall insulation effectiveness. When installing full fill cavity insulation, it is important to follow specific installation techniques to ensure optimal performance. This includes using suitable insulation materials that are designed to fit the cavity dimensions and provide a high level of thermal resistance. By completely filling the cavity, full fill insulation eliminates potential pathways for heat transfer and reduces air infiltration, resulting in improved energy efficiency.

Full fill cavity insulation completely fills the cavity and creates a continuous thermal barrier, maximizing energy efficiency and enhancing overall insulation effectiveness. When installing full fill cavity insulation, it is important to follow specific installation techniques to ensure optimal performance. This includes using suitable insulation materials that are designed to fit the cavity dimensions and provide a high level of thermal resistance. By completely filling the cavity, full fill insulation eliminates potential pathways for heat transfer and reduces air infiltration, resulting in improved energy efficiency.

One of the key advantages of full fill cavity insulation is its ability to prevent thermal bridging. Thermal bridging occurs when there is a direct conduction path between the interior and exterior of a building, bypassing the insulating layer. With full fill insulation, the continuous thermal barrier minimizes the risk of thermal bridging, ensuring that heat is not lost or gained through structural components.

When compared to other insulation methods, full fill cavity insulation offers superior energy efficiency benefits. The complete filling of the cavity eliminates air gaps and reduces the overall heat loss, resulting in reduced energy consumption and lower heating and cooling costs. Additionally, the continuous thermal barrier provided by full fill insulation enhances the insulation effectiveness, maintaining a more consistent and comfortable indoor temperature.

However, it is important to note that full fill cavity insulation may require professional expertise for installation, as precise techniques are necessary to ensure proper filling and avoid thermal bridging. Moreover, the availability of suitable insulation materials for full fill cavity insulation may be limited. This insulation method is more commonly used in new construction projects rather than retrofitting existing buildings.

Full Fill Cavity Wall Construction is Not Recommended in All Areas

It is important to note that a fully filled cavity is not recommended in some parts of the country due to the risk of moisture penetration. Therefore, the design and construction of the cavity wall must comply with the relevant sections of Agrément Certificate 14/5157.

This specialist cavity wall product is designed to perform at its best when the gaps between boards are kept to a minimum. This is achieved by using precision straight edges. The quality and accuracy of the brickwork and blockwork are also important, as they must ensure that there is a 10mm clear space in the 100mm cavity.

The boards should never be pushed into the cavity. Instead, the inner leaf should always be constructed ahead of the outer leaf. This will allow any mortar to be cleaned off the back of the inner leaf before the boards are installed.

Building control surveyors and our business partners, LABC Warranty, will also inspect the work as it progresses to ensure that mortar snots, spacer placement, and inaccurate bricklaying do not bridge the remaining cavity. This will help to ensure that the wall performs as it is designed to.

Summary of Full Fill

With care and skill, a high-performance solution can be achieved that will keep the householder warm and cosy, while also reducing energy costs.

When compared to other insulation methods, full fill cavity insulation offers superior energy efficiency benefits. The complete filling of the cavity eliminates air gaps and reduces the overall heat loss, resulting in reduced energy consumption and lower heating and cooling costs. Additionally, the continuous thermal barrier provided by full-fill insulation enhances the insulation effectiveness, maintaining a more consistent and comfortable indoor temperature.

However, it is important to note that full fill cavity insulation may require professional expertise for installation, as precise techniques are necessary to ensure proper filling and avoid thermal bridging. Moreover, the availability of suitable insulation materials for full fill cavity insulation may be limited. This insulation method is more commonly used in new construction projects rather than retrofitting existing buildings.

Partial Fill Cavity Wall Insulation

Partial fill cavity wall insulation offers a more cost-effective option for insulation and is suitable for retrofitting in existing buildings. It provides an easier and quicker installation process compared to full fill insulation. This type of insulation is available in a wide range of materials, making it more accessible for homeowners and builders.

Partial fill cavity wall insulation offers a more cost-effective option for insulation and is suitable for retrofitting in existing buildings. It provides an easier and quicker installation process compared to full fill insulation. This type of insulation is available in a wide range of materials, making it more accessible for homeowners and builders.

However, it is important to note that partial fill insulation may leave air gaps between the insulation and the masonry, potentially leading to reduced insulation effectiveness and thermal bridging if not properly installed.

In terms of cost comparison, partial fill cavity wall insulation generally tends to be more affordable than full fill insulation. This makes it an attractive option for those looking to improve the energy efficiency of their homes without breaking the bank. Additionally, the retrofitting process can present challenges, as existing buildings may have limitations or constraints that need to be considered during installation.

When it comes to energy efficiency comparison, partial fill insulation offers a significant improvement over uninsulated walls. It helps reduce heat loss and energy consumption, leading to lower heating and cooling costs. However, full fill insulation provides a more continuous thermal barrier, offering higher energy efficiency compared to partial fill insulation.

Overall, partial fill cavity wall insulation is a cost-effective solution for retrofitting existing buildings. While it may have some drawbacks such as potential gaps and reduced insulation effectiveness compared to full fill insulation, it still provides significant energy efficiency benefits. Proper installation and regular maintenance are crucial to ensure its performance and effectiveness in reducing heat loss and improving energy efficiency.

Benefits of Full Fill Cavity Insulation

One advantage of cavity insulation that completely fills the space is its ability to create a continuous thermal barrier. This means that there are no gaps or air pockets within the insulation, which maximizes its energy efficiency and enhances its overall insulation effectiveness. By completely filling the cavity, full fill cavity insulation eliminates potential pathways for heat transfer and reduces air infiltration, resulting in reduced heat loss and energy consumption.

In terms of installation process, full fill cavity insulation requires precise installation to avoid thermal bridging. Thermal bridging occurs when there is a direct pathway for heat transfer through materials with high thermal conductivity, such as metal framing or masonry ties. Therefore, proper installation techniques and attention to detail are crucial to ensure that the insulation is properly installed and thermal bridging is minimized.

However, retrofitting full fill cavity insulation in existing buildings can be challenging. It requires professional expertise and may be more expensive compared to partial fill insulation. Additionally, the availability of suitable insulation materials for full fill cavity insulation may be limited in certain regions.

Drawbacks of Partial Fill Cavity Wall Insulation

A drawback of partial fill insulation is the potential for air gaps between the insulation and masonry, which can compromise its overall effectiveness in reducing heat loss and energy consumption. These potential air gaps can occur due to improper installation or settling of the insulation over time. When air gaps exist, heat can easily transfer through the gaps, leading to thermal bridging concerns. Thermal bridging occurs when there is a direct pathway for heat transfer between the inside and outside of a building, bypassing the insulation's thermal resistance. As a result, the insulation's effectiveness in preventing heat loss is lower compared to full fill insulation, where the entire cavity is filled without any gaps.

Another limitation of partial fill insulation is its limited soundproofing capabilities. Since air gaps can exist between the insulation and the masonry, sound can easily pass through these gaps, reducing the insulation's ability to provide acoustic insulation. Therefore, if soundproofing is a priority, full fill insulation may be a more suitable option.

Partial fill cavity wall insulation also requires regular maintenance and inspection to ensure its performance. Over time, the insulation may settle or degrade, leading to the formation of additional air gaps or reduced insulation effectiveness. Regular inspections and maintenance are necessary to identify and address any issues to maintain the insulation's energy-saving properties effectively.

What is a residual cavity?

The residual or nominal cavity in a cavity wall insulation system serves two purposes. First and foremost, it allows the bricklayer to easily position the outer leaf of brick or block. This would be difficult and time-consuming if the cavity were fully filled with rigid insulation boards.

Second, the low-emissivity aluminium facing of the insulation board reflects heat back out of the building, improving thermal performance. Insulation retaining discs are used to maintain a 10mm cavity between the insulation facing and the outer leaf, which is the optimum spacing for thermal performance.

The minimum residual cavity width is 25mm for buildings up to 12m high. This is the minimum width that will prevent moisture from penetrating the inner leaf of the wall. However, it is recommended to design a 50mm wide cavity to allow for inaccuracies in the building process. This means that the cavity boards can be installed without any gaps, which will help to prevent moisture from penetrating the wall.

In areas of very severe exposure, such as coastal areas, a 75mm residual cavity is required. This is because the wind and rain in these areas can be more likely to cause moisture to penetrate the wall.

It is important to keep the residual cavity clean and free of mortar snots and debris that can help moisture cross the cavity. This can be done by sweeping the cavity regularly and removing any debris that is found.

Above doors, windows and other openings, a cavity tray should be installed to protect the lintel. A cavity tray is a metal or plastic sheet that is installed in the cavity to catch any moisture that penetrates the wall. The cavity tray should have weepholes that allow the moisture to drain away.

Cavity trays may also be needed for projections and discontinuities within the cavity such as ring beams. A ring beam is a concrete beam that is used to support the lintel above a door or window opening. The ring beam can create a discontinuity in the cavity, which can allow moisture to penetrate the wall. A cavity tray can be installed to prevent this from happening.

The specific requirements for residual cavity width will vary depending on the location of the building, the exposure rating, and the type of finish that is being applied. It is important to consult with a local building control authority to confirm the requirements for a particular project.

Choosing the Right Cavity Wall Insulation

When selecting the appropriate insulation method for a building, it is crucial to consider factors such as thermal performance, cost-effectiveness, ease of installation, and retrofitting suitability.

Cost considerations play a significant role in determining the most suitable insulation method for cavity walls. Full fill cavity insulation may be more expensive than partial fill insulation due to the higher material and installation costs. However, the superior thermal performance of full fill insulation can result in significant energy savings in the long run.

Thermal bridging is another important consideration when choosing the right cavity wall insulation. Full fill insulation minimizes thermal bridging by creating a continuous thermal barrier, while partial fill insulation may have gaps that can allow heat transfer. This can impact the overall insulation effectiveness and energy efficiency of the building.

Retrofitting challenges should also be taken into account. Full fill insulation is more suitable for new construction, as it requires precise installation and may be difficult to retrofit in existing buildings. On the other hand, partial fill insulation is a cost-effective option for retrofitting, as it is easier and quicker to install. However, regular maintenance and inspection are required to ensure its performance.

Finally, the choice of insulation material options is a key factor in selecting the right cavity wall insulation. Full fill insulation may have limited availability of suitable materials, while partial fill insulation benefits from a wide range of options. It is important to consider the specific requirements of the building, such as soundproofing capabilities, in order to make an informed decision.

Insulation and Installation of Wall Insulation Boards

The process of insulating, whether through full or partial fill, mandates exactitude and expertise. During partial fill installations, insulation batts or boards are methodically positioned on the inner leaf of the cavity wall, establishing a uniform and efficient insulation layer. Blown wall insulation, where insulation material is blown into the cavity, constitutes another technique that demands meticulous execution. Wall insulation boards, concocted from diverse materials including PIR, EPS (expanded polystyrene), and mineral wool, present adaptability in electing the right insulation for specific project requisites. The choice between full and partial fill methods hinges on a comprehensive assessment of cavity composition and the sought-after thermal performance, contributing to a masonry wall endowed with energy efficiency and insulation prowess.

Contrasting Full Fill and Partial Fill Approaches

Choosing between full-fill and partial-fill cavity insulation pivots upon numerous considerations, encompassing cavity width and the coveted insulation value. Partial fill insulation options, encompassing mineral wool and blown insulation, manifest versatility and ease of installation. These are positioned within the cavity while preserving an appropriate residual space to counteract thermal bridging. Conversely, full-fill solutions like Celotex Thermaclass Cavity Wall 21 and the offerings from Saint-Gobain Insulation saturate the cavity completely, often employing rigid insulation like PIR.

Opting for the Right Cavity Insulation Type

When navigating the realm of ideal insulation for masonry cavity walls, an exhaustive grasp of the building's requisites takes precedence. Perusing the Thermaclass Cavity Wall 21 product brochure yields invaluable insights into its specifications and applications. Variables such as insulation value, installation simplicity, and synergy with other components in the wall's constitution inform the judicious selection of insulation type. This decision carries significant weight in terms of energy efficiency and adherence to building regulations. Whether realized through comprehensive cavity saturation or partial fill techniques, precise installation guarantees a thermally efficient masonry cavity wall, fostering a sustainable and comfortable constructed milieu.

Our Cavity Wall Insulation Products Range

Knauf Dritherm 37 - Mineral Wool Cavity Wall Insulation:

Knauf Dritherm 37 is a premium mineral wool insulation designed for cavity walls. It boosts energy efficiency, minimizes heat loss, and offers soundproofing. Easy to install and environmentally friendly, it's an excellent choice for enhancing building insulation.

Celotex Thermaclass Cavity Wall 21 - Cavity Wall Insulation Board

Celotex Thermaclass Cavity Wall 21 is a specialized insulation board designed for cavity walls. It provides efficient insulation, promoting energy savings and comfort. Ideal for enhancing building thermal performance.

Knauf Dritherm 32 - Cavity Batt Insulation

Knauf Dritherm 32: Engineered for cavity walls, this premium solution offers outstanding thermal efficiency and elevated comfort levels. Its advanced design ensures seamless installation, effectively minimizing heat loss and enhancing energy conservation. Perfectly suited for various building types, Knauf Dritherm 32 Cavity Batt Insulation stands as a reliable choice to optimize insulation performance and create more comfortable living and working spaces.

HEMSPAN® Bio Flex - 50mm Hemp Wool Insulation Batts

HEMSPAN® Bio Flex: 50mm hemp wool insulation batts. , combining sustainability and effectiveness. Crafted from natural hemp fibers, these insulation batts offer eco-friendly thermal enhancement. With a slim 50mm profile, they seamlessly fit into diverse spaces, making them an efficient choice for environmentally conscious insulation projects. Embrace green insulation with HEMSPAN® Bio Flex Hemp Wool Insulation Batts.

HEMSPAN® Bio Flex - Hemp Wool Insulation - Pallet Quantities

HEMSPAN® Bio Flex Hemp Wool Insulation in Pallet Quantities: A bulk solution for sustainable insulation projects. These hemp wool insulation batts, available in pallet quantities, offer eco-friendly and efficient thermal performance. Ideal for larger-scale applications prioritizing both environmental consciousness and effective insulation.

Frequently Asked Questions

Q: What Are the Potential Drawbacks of Full Fill Cavity Insulation That Homeowners Should Be Aware Of?

When considering full fill cavity insulation, homeowners should be aware of several potential drawbacks. These include the need for precise installation to avoid thermal bridging, which can compromise the insulation's effectiveness.

Full fill insulation may also be more expensive than partial fill options and may have limited availability of suitable materials.

Retrofitting full fill insulation in existing buildings can be challenging, requiring professional expertise.

Additionally, homeowners should consider the impact on indoor air quality and the potential for moisture issues when choosing this type of insulation.

Q: Can Partial Fill Cavity Wall Insulation Be Used in New Construction Projects or Is It Primarily for Retrofitting Existing Buildings?

Partial fill cavity wall insulation can be used in new construction projects, providing several benefits. It offers a cost-effective option for insulation, reducing heat loss and energy consumption. The wide availability of insulation materials makes it suitable for new buildings.

However, it is important to consider building regulations and standards for its use. Case studies have demonstrated the successful implementation of partial fill cavity insulation in new constructions.

The environmental impact of partial fill cavity insulation in new buildings should also be explored.

Q: How Do Full Fill vs Partial Fill Cavity Insulation Differ in Terms of Their Soundproofing Capabilities?

In terms of soundproofing capabilities, full fill and partial fill cavity insulation differ.

Full fill insulation, which completely fills the cavity, offers more soundproofing capabilities due to having more mass than partial fill.

On the other hand, partial fill insulation, which leaves an air gap, may have lower overall insulation effectiveness and therefore provides less soundproofing.

When comparing the two insulation methods, full fill insulation is more effective at reducing sound transmission compared to partial fill insulation.

Q: What Are Some Alternative Options to Cavity Wall Insulation for Improving Energy Efficiency in Buildings?

Alternative options for improving energy efficiency in buildings include:

- External cladding: Provides additional insulation and protection from the elements.

- Roof insulation: Helps prevent heat loss through the roof.

- Double glazing: Reduces heat transfer through windows.

- Solar panels: Generate renewable energy and reduce reliance on traditional power sources.

These options can help enhance energy efficiency in buildings, reducing energy consumption and environmental impact.

Q: What is full fill insulation for cavity walls?

A: Full fill insulation for cavity walls refers to the practice of completely filling the cavity between the inner and outer leaf of a masonry cavity wall with insulation material. This ensures that the entire cavity is properly insulated, leaving no gaps or voids.

Q: What is partial fill insulation for cavity walls?

A: Partial fill insulation for cavity walls involves filling only a portion of the cavity with insulation material. This is typically done by installing insulation boards or panels on the interior face of the inner leaf, leaving a defined air gap between the insulation and the outer leaf of the wall.

Q: What are the benefits of full fill insulation?

A: Full fill insulation provides enhanced thermal performance by completely filling the cavity and eliminating any thermal bridges. It helps to reduce heat loss, improve energy efficiency, and enhance the overall comfort of the building. Full fill insulation also helps to meet building regulations and improve the SAP (Standard Assessment Procedure) rating of a property.

Q: What are the benefits of partial fill insulation?

A: Partial fill insulation offers the advantage of easier installation as compared to full fill insulation. It allows for the use of wider cavities, which can help with better ventilation and drainage. Partial fill insulation also provides flexibility in terms of choosing the thickness and type of insulation, and it can be a cost-effective solution in certain scenarios.

Q: What are the insulation options for masonry cavity walls?

A: The insulation options for masonry cavity walls include both full fill and partial fill insulation. Full fill options include products like PIR (Polyisocyanurate) insulation boards or blown wall insulation, which is installed by injecting insulation material into the cavity. Partial fill options include cavity insulation boards or wool insulation, which are fixed onto the inner leaf of the wall.

Q: Are there any considerations for choosing between full fill and partial fill insulation?

A: Yes, there are several factors to consider when choosing between full fill and partial fill insulation. These include the width of the cavity, the type of construction, the desired thermal performance, the building regulations, and any specific requirements of the project. It is recommended to consult with a qualified professional or follow the manufacturer's guidelines to make an informed decision.

Q: Are there any building regulations related to cavity wall insulation?

A: Yes, there are building regulations related to cavity wall insulation. In the UK, for example, Part L of the Building Regulations sets out the requirements for energy efficiency in buildings, including provisions for thermal insulation. Compliance with these regulations is important for ensuring the energy efficiency and sustainability of a building.

Q: Can full fill insulation be used for masonry cavity walls?

A: Yes, full fill insulation can be used for masonry cavity walls. It involves completely filling the cavity with an appropriate insulation product, such as PIR insulation boards or blown wall insulation, to provide optimum thermal performance and energy efficiency.

Q: Can partial fill insulation be used for masonry cavity walls?

A: Yes, partial fill insulation can also be used for masonry cavity walls. It typically involves fixing insulation boards or panels onto the interior face of the inner leaf, leaving a gap between the insulation and the outer leaf. This method provides thermal insulation while allowing for ventilation and drainage.

Q: How is partial fill cavity insulation installed?

A: Partial fill cavity insulation is installed by fixing insulation boards onto the internal face of the inner leaf of a masonry cavity wall. The boards are securely attached using appropriate fixings, and the joints between the boards are sealed to prevent any air leakage. It is important to follow the manufacturer's installation guidelines and ensure that the insulation is properly fitted and well-sealed.

Q: What are some recommended insulation solutions for cavity walls?

A: Some recommended insulation solutions for cavity walls include full fill PIR insulation boards, blown wall insulation, cavity insulation boards, and wool insulation. These products offer good thermal performance and energy efficiency when installed correctly and in accordance with the specific requirements of the project.

In conclusion, the choice between full-fill and partial-fill cavity wall insulation hinges on a careful evaluation of various factors to ensure optimal energy efficiency, cost-effectiveness, and suitability for the project at hand. Full-fill insulation offers the advantage of creating a continuous thermal barrier, eliminating thermal bridging, and maximizing overall insulation effectiveness. Although it requires precise installation techniques, it guarantees superior energy efficiency and reduced heating and cooling costs. Partial-fill insulation, on the other hand, provides a cost-effective solution for retrofitting existing buildings, allowing for easier installation and accessibility to various insulation materials. However, potential air gaps and lower insulation effectiveness must be managed through proper installation and maintenance.

Ultimately, the decision should consider the building's specific requirements, such as thermal performance, soundproofing needs, and retrofitting feasibility. Each insulation approach offers its own set of benefits and challenges, aiming to contribute to a more energy-efficient and comfortable built environment. As construction practices and insulation materials continue to evolve, making informed choices about cavity wall insulation methods remains essential for achieving sustainable and efficient building designs.

Samuel Hitch

Managing Director

Buy Insulation Online.

Leave A Reply

Your feedback is greatly appreciated, please comment on our content below. Your email address will not be published. Required fields are marked *