Request a Quote

Our team is happy to fulfil custom orders, offer special bulk discounts you cannot get from the website. Please get in touch today to discuss your needs.

Thermal insulation jackets are possibly the most innovative and smart way to insulate flanges. Our expert opinion is that they far outperform the traditional rigid wool insulation that has been used to insulate valves, and here is why:

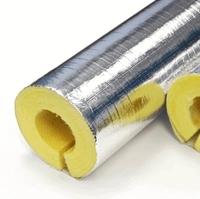

Their make: The valve covers that we supply here at Buy Insulation online are made with the finest quality silicone glass cloth. We use 50mm mineral wool for insulation. Valve jackets are cost-effective.

Thermal Insulation: We use low thermal conductivity mineral wool insulation to protect flanges from heat loss. So valve jackets help save energy and money. This is particularly useful in any commercial and industrial setting.

Easy Installation and Maintenance: As flanges are important connecting points in the piping system it is important to keep them well-maintained. Valve covers help you do just that. They ease the maintenance process and reduce the time required by half. Simply remove the velcro straps and loosen the pull cords to uninstall the valve covers.

Also, unlike rigid wool insulation that is used to insulate valves, valve covers can be removed without harming the insulation or the pipework.

Safer Workplace: Valve covers protect your workforce from hot surfaces of flanges, making the workplace safer. They also minimise any external damage to the flanges. Due to their insulating properties, they reduce condensation and sweating in flanges. As a result, water does not drip, which keeps the workplace from accumulating tiny pools of water. This helps prevent accidents and slips and falls.

Protection from moisture and damage: The external valve covers for flange unions are made with PVC cloth on the outer and silicone glass cloth on the inner side of the cover. The PVC cloth makes these valve jackets waterproof and more resilient to damaging external conditions.

Product Specification:

- Product Sizes: 15mm, 20mm, 25mm, 32mm, 40mm, 50mm, 65mm, 77mm, 100mm, 125mm, 150mm, 200mm, 250mm and 300mm

- Colours: Standard grey, silver, white and standard black.

- Service Temperature: -20 °C to +220 °C

- Insulation: 50mm Rockwool

- Type:

- External Valve Covers: Made with waterproof PVC cloth on the outside and silicone glass cloth on the inner side.

- Internal Valve jackets: They are made with silicone glass cloth on both sides.

Key Features:

- Flange covers provide effective thermal insulation around flange union valves.

- They are lightweight, easy to use, handle and install.

- Valve jackets provide fully sealed insulation to avoid any airborne contamination and possible harm to personnel.

- They help reduce energy bills.

- The velcro flaps and pull cords in the valve jackets ensure a perfect fit around the valves.

- They are cost-effective and convenient.

- Valve jackets protect the valves from dirt, dust and rust.

- They improve workplace safety by reducing the heat emitted by the surface

- Flange covers are made from silicone glass fibre cloth sewn around 50mm of insulation.

Applications:

Valve jackets are designed to closely fit around awkward flange union valves to maximise insulation and remove possible sharp edge hazards.

Note:

- All Valve jackets are made to order, No returns, refunds or exchanges will be applicable. If you are unsure of the size, please email us a picture of the valve and its dimensions for our experts to access and make the valve covers suitable for your application. We will assist you in any way we can.

- Lead times for screwed valve covers within the UK: 1-10 units: 5-7 working days, Anything above that, please email us for the lead times.

- We do site surveys and supply valve covers or we can only survey your premises. If you would like a site survey, kindly email us with your site address.

- The prices for the chilled/cold water valve jackets may differ from the ones displayed on the website. Chilled/cold water valves usually need to be wrapped with a vapour barrier which would increase the size of the jacket required and also the cost. If you need chilled/cold water valve covers, please mail us your requirements at enquiries@buyinsulationonline.co.uk and we will send you a quote for your order.

- Flange union valve covers are available in sizes ranging from 1/2 an inch to 12 inches.

- They are also available in different colours - standard grey, standard black, silver, white

- Valve covers give a superior finish as they are made with silicone glass cloth

- Thermal insulation jackets are easy to install.

- Insulation jackets give airtight insulation around flanges and prevent heat loss.

- Valve jackets provide effective insulation in temperatures ranging from -20 °C to +220 °C

- Valve covers increase workplace safety and reduce maintenance time by half.

- All valve covers are made to order and NON REFUNDABLE

| Insulation Type | Flange Covers |

| Cloth Material | Silicone glass cloth, PVC |

| Insulation | Mineral Wool |

| Suitable for | Flange Unions |

| Colours Available | Standard Black, White, Silver and Standard Grey |

| Standard Sizes | 15mm, 20mm, 25mm, 32mm, 40mm, 50mm, 65mm, 77mm, 100mm, 125mm, 150mm, 200mm, 250mm and 300mm. |

| Service Temperature |

-20 °C to +220 °C |

| Delivery Terms | |

|---|---|

| Order Value (Excluding VAT) | Delivery Charge (Excluding VAT) |

| Above £390 | Free delivery |

| Up to £390 | £15 |

Product: All valve covers are made to order and NON-REFUNDABLE. If you are unsure of the size, please email us a picture of the valve and its dimensions for our experts to access and make the valve covers suitable for your application. We will assist you in any way we can.

We welcome you to share information on the pipe insulation thickness and images of your application along with the order to help us get your requirement correctly.

If you require a quote for these valve jackets, please email us with your requirements

Lead time: Lead time for quantities 1-10 is about 5-7 working days. For anything above please email us for the lead times.

Returns and cancellations:

You are free to cancel your order before we confirm your order via email. Once an order confirmation email is sent, cancellations, returns and refunds will not be acceptable.

Additional information:

- We do site surveys and supply valve covers or we can only survey your premises. If you would like a site survey, kindly email us your site address or fill the contact form above.

- The prices for the chilled/cold water valve jackets may differ from the ones displayed on the website. Chilled/cold water valves usually need to be wrapped with a vapour barrier which would increase the size of the jacket required and also the cost. If you need chilled/cold water valve covers, please mail us your requirements and we will send you a quote for your order.

- We also make valve covers in red, blue and green colours. If you have any such requirements, please get in touch with us.

Customer Reviews

“ I was looking for some weatherproof jackets for the outside flanges. Found this company online and s...”Stanley S.

“ Very quick turnaround. faster than anyone we have worked with. thank you very much”Andrew P.

“ The delivery was quick. faster turnaround than any company I have worked with. good prices too”Ralph B.

“ Very happy and highly satisfied with my purchase. good buy”Nathan H.

“ This was hands down the best product and company we have used for valve insulation. Great going guys...”Jasper G.

“ As an insulation contractor, I use valve muffs quite often. This company gave me the best prices for...”Sam M.

“ It fit as expected. thank you”Alex B.

“ There are many similar products available in the market for this purpose, but the quality and the pr...”Asif M.

“ The valve bag fit perfectly, good stuff”Joseph C.

“ the 2 inch jacket fit perfectly around the flange. definitely buying more from these guys”Christopher B.

Our Customers Include

To optimise efficiency and minimise heat loss in your piping systems, consider insulating flange unions. These coverings help enhance operational performance, maintain consistent temperatures, and save money. Made from silicone-coated glass fabric and mineral wool, they are offered in various sizes and can withstand temperatures from -20°C to +220°C. Removable jackets improve maintenance, system efficiency, and energy efficiency while supporting environmental targets. Proper installation, using high-quality materials, and regular inspections for damage are crucial for optimal performance. For long-term benefits in your industrial processes, investing in insulating flange unions is a wise decision.

Key Points

- Silicone glass cloth and mineral wool insulation materials are used.

- Available in various sizes suitable for different pipes.

- Enhances thermal efficiency in industries.

- Detachable jackets for improved maintenance and energy savings.

- Follow installation tips for optimal performance and longevity.

Significance of Flange Union Insulation

Flange union insulation is essential for maintaining temperature stability and preventing heat loss in piping systems. By insulating the connection points of pipes with flange union insulation jackets, you're ensuring that your system operates efficiently, leading to significant cost savings and energy conservation. These insulation jackets act as a barrier, reducing heat transfer and preventing energy wastage. Investing in proper insulation not only helps in keeping your operational costs low but also contributes to a more sustainable environment by decreasing energy consumption.

Cost efficiency is a critical aspect when considering flange union insulation. By reducing heat loss through insulation, you're effectively cutting down on the amount of energy needed to maintain ideal temperatures in your piping system. This translates to long-term savings on energy bills and maintenance costs. Energy savings go hand in hand with cost efficiency, as the less energy you use, the more you save in the long run. Proper insulation is a smart investment that pays off through reduced expenses and improved system performance.

Types of Insulation Jackets Available

When exploring the variety of insulation jackets available, you'll find a range of sizes tailored to different pipe diameters. Here are some key points to consider:

- Insulation Materials: Flange union insulation jackets are crafted with silicone glass cloth and 50mm mineral wool insulation. This combination guarantees effective thermal insulation properties, helping to maintain temperature stability and prevent heat loss around flanges.

- Sizing Options: These jackets come in various sizes, ranging from 1/2 inch to 12 inches, catering to a wide range of pipe diameters. This versatility allows you to select the appropriate jacket size for your specific industrial application needs.

- Versatile Usage: Suitable for temperatures between -20°C to +220°C, these insulation jackets offer a broad range of applications across different industries. Their airtight design around flanges provides protection against energy loss, making them a reliable choice for ensuring thermal efficiency in various settings.

Advantages of Using Detachable Jackets

Using removable jackets on your industrial equipment can greatly improve maintenance efficiency and system performance. These jackets offer several benefits that can positively impact your operations.

Firstly, cost savings are a significant advantage of using removable jackets. By preventing heat loss and improving energy efficiency, these jackets can help reduce your energy costs over time.

Secondly, environmental protection is another key benefit. The insulation provided by these jackets not only helps in conserving energy but also reduces your carbon footprint by lowering greenhouse gas emissions.

Installation Tips for Maximum Efficiency

For peak efficiency when installing insulation jackets on your industrial equipment, ensure precise alignment and fit by accurately measuring the flange or union beforehand. To ensure maximum energy savings and effectiveness, follow these installation techniques:

- Essential Materials: Use high-quality materials like silicone glass cloth and mineral wool insulation to provide efficient thermal protection. Selecting the right materials is essential for long-lasting insulation performance.

- Secure Installation: Secure the insulation jacket tightly around the flange or union to prevent heat loss and maintain efficiency. A snug fit is vital to optimise energy savings and thermal insulation benefits.

- Regular Inspection: Regularly inspect the insulation jacket for any damage or wear and tear to ensure peak performance. Monitoring the condition of the insulation helps maintain its effectiveness over time.

Maintenance and Care Guidelines

To ensure your insulation jackets perform at their peak and last a long time, regular maintenance and care are crucial. It's important to check your insulation jackets frequently for tears, signs of wear, or damage to ensure they are working effectively.

Clean them with a gentle detergent and water solution to get rid of dirt and debris, while avoiding strong chemicals that could cause harm to the materials. Make sure the jackets are properly secured to maintain their efficiency. Always adhere to the manufacturer's instructions for maintenance to prolong their lifespan.

When it comes to repairs, make sure to deal with any tears promptly to prevent further problems. It's also a good idea to take preventive action by keeping the jackets clean and well looked after. Remember to take safety precautions, like avoiding putting too much stress on the jackets.

Commonly Asked Questions

What is a Flange Jacket?

A flange jacket keeps your equipment safe by preventing heat loss and shielding from hot surfaces. The installation process is simple, using velcro straps for a secure fit. Enjoy the benefits of improved safety and efficiency.

Which Insulation Is Best for Jackets?

For the best insulation jackets, consider materials like silicone glass cloth with mineral wool. These types offer low thermal conductivity, ensuring heat retention. Maintain temperature stability and energy efficiency with airtight insulation options. Personalise for top fit.

How do you insulate flanges?

To insulate flanges effectively, wrap them with materials like silicone glass cloth and mineral wool to retain heat and improve energy efficiency. This simple step not only protects from heat but also reduces costs.

What is the purpose of flange insulation?

For you, the importance of flange insulation is crucial. It enhances thermal efficiency, offering cost-effective solutions for energy savings and reducing environmental impact. Be part of the community that prioritises safety, sustainability, and optimal performance.

Summary

In summary, flange union insulation jackets play a vital role in maintaining the efficiency and longevity of industrial equipment.

By selecting the appropriate type of insulation jacket and following proper installation and maintenance guidelines, you can guarantee peak performance and energy savings.

Investing in removable jackets can also make maintenance tasks easier and more cost-effective in the long run.

Remember to prioritise insulation for your flange unions to maximise efficiency and prevent heat loss.